Blasting and automation

ENETEX TECHNOLOGY, s.r.o. is a dynamic engineering company whose main goal is to meet clients’ demands and needs in the area of automation of production process. At client’s request it develops and manufactures single-purpose machines for automation and half automation of production, up to robotic stations including technological equipment.

Robotics and automation in production process

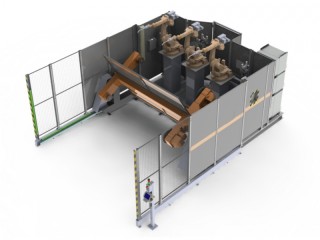

Speed and readiness are important elements if we want to succeed and be competitive, we must not forget to adjust. That means to robotize and automate production process. ENETEX TECHNOLOGY company provides means forautomation of production process such as robotic welding, blasting and process handling. These are carried out using blasting cabins Basic and Compact, robotic stations, and other equipment to support these procedures (cleaning of welding torches, control stations for welding wire and non-stick liquid)

Robotics specializes in:

- complete robotic welding units,

- complete robotic stations,

- cleaning stations for robotic welding torches,

- cleaning stations for manual welding torches,

- welding wire control stations,

- milling cutters, brushes, non-stick liquid,

- robotic grippers for automotive industry,

- pneumatic engines,

- planetary gears,

- pneumatic clamps,

- electric tools for general engineering use.

Automation

Single-purpose machines are designed in accordance with client’s demands for specific automation of production in the fields of handling, assembling, welding, cutting etc. The drives of the machines are electric or pneumatic operated by central logic or PLC automatic machine. In the area of robotics the company offers welding robotic stations with small manually turning tables up to big electrically turning work stations with electrically turning tables. The stations can be chosen from many standard versions or can be adjusted and designed according to client’s demand.Another part of the production line are robotic units. These are welding units with mechanic or automatic opening/turning of the doors in the production program of the company. In case of space demands it is possible to adjust the size of the unit in accordance to the size of the robot, eventually in accordance to the room available for the work station.Within the scope of robotics the company has developed a cleaning unit of welding torches by milling and blasting and a welding wire inspection unit.